Content

Attention:this article is intended for people over 18 years of age.

Many of the home breweries are just steps away from becoming commercial. A 22.7 liter homebrewery can be converted into a commercial one. Although, for better performance, it is recommended to take at least 45.46 liters. The 250 liter boilers can be used for large breweries with a working capacity of about 158.9 liters.

If you are planning to start a commercial operation or even start the production of a brewery plant with a bottling line, it is wise to use a large home brewing plant as an entry point for a commercial operation. And when the project is approved, your home brewery will magically turn into a commercial one. The truth is that often breweries cannot immediately produce enough beer to make a big profit and you may not be selling your beer outside of your city, however, you can expand your production over time, make all your dreams come true and enjoy the process. making great beer!

Steps

1 Determine what you want to use your brewery for. Of course, you want to make beer that will be liked by those around you. It makes sense to start small because it can take a year before a plant project is approved, and there is always a risk that you might be rejected due to the location or condition of the building that will house your plant. You must have a beer production system in place before your project is approved. So why risk many thousands of dollars for a commercial brewery and associated infrastructure like a steam boiler, glycol dispensing system, and industrial electronic controls when you can use a home setup for initial approval? Once your brewery is approved, you can update it at will. It can take you many months to build a large brewery. If you think this is a good idea, you should understand that you can't just grab and drag a RIMS (Recirculating Infusion Mash System), MoreBeer sculpture, or your home installation onto a commercial site and invite an inspector to check. There are certain technical hurdles that you will need to overcome and you probably don't want additional reviews as this will slow down the approval process significantly.

1 Determine what you want to use your brewery for. Of course, you want to make beer that will be liked by those around you. It makes sense to start small because it can take a year before a plant project is approved, and there is always a risk that you might be rejected due to the location or condition of the building that will house your plant. You must have a beer production system in place before your project is approved. So why risk many thousands of dollars for a commercial brewery and associated infrastructure like a steam boiler, glycol dispensing system, and industrial electronic controls when you can use a home setup for initial approval? Once your brewery is approved, you can update it at will. It can take you many months to build a large brewery. If you think this is a good idea, you should understand that you can't just grab and drag a RIMS (Recirculating Infusion Mash System), MoreBeer sculpture, or your home installation onto a commercial site and invite an inspector to check. There are certain technical hurdles that you will need to overcome and you probably don't want additional reviews as this will slow down the approval process significantly.  2 Find a location for your brewery. Breweries should be located in suitable areas in accordance with local regulations. It is unlikely that it would be legally legal to host a brewery in your home. Light industry areas are ideal for brewery locations. The main thing is that there are no schools and churches nearby.The building must have wiring and drainage systems as it is necessary for the production of the product.

2 Find a location for your brewery. Breweries should be located in suitable areas in accordance with local regulations. It is unlikely that it would be legally legal to host a brewery in your home. Light industry areas are ideal for brewery locations. The main thing is that there are no schools and churches nearby.The building must have wiring and drainage systems as it is necessary for the production of the product.  3 Adapt to the floor in the building. The number of storeys of a building is a significant factor. Concrete floors are a must. A brewery in which liquid flows to the floor must ensure that the floor is at a certain slope so that the liquid flows properly down the drain. But if you are using a small home installation, then there is no need for a complex drainage system. Just be aware that if you are upgrading your installation, you will likely need to upgrade your drainage system as well. Check what types of drainage systems you need before purchasing a building or applying for a loan. Some breweries install drainage systems after purchasing the premises, but before installing your brewing equipment. It is allowed that only the area under the installation itself is tilted. This site should also be equipped with sewerage. In the part of the brewery where customers will gather, the floors should of course be normal.

3 Adapt to the floor in the building. The number of storeys of a building is a significant factor. Concrete floors are a must. A brewery in which liquid flows to the floor must ensure that the floor is at a certain slope so that the liquid flows properly down the drain. But if you are using a small home installation, then there is no need for a complex drainage system. Just be aware that if you are upgrading your installation, you will likely need to upgrade your drainage system as well. Check what types of drainage systems you need before purchasing a building or applying for a loan. Some breweries install drainage systems after purchasing the premises, but before installing your brewing equipment. It is allowed that only the area under the installation itself is tilted. This site should also be equipped with sewerage. In the part of the brewery where customers will gather, the floors should of course be normal.  4 Your brewery must be hygienic. The brewery belongs to the food industry, but it goes without saying that beer does not carry the same risks as food. It cannot contain pathogenic bacteria and viruses. However, you should have two stainless steel sinks that have an air gap between the drain and the floor (there should be room for wastewater) and a separate sink for washing your hands. If you want to avoid sanitary checks and minimize the rules you have to comply with, don't plan on serving your beer at the brewery.

4 Your brewery must be hygienic. The brewery belongs to the food industry, but it goes without saying that beer does not carry the same risks as food. It cannot contain pathogenic bacteria and viruses. However, you should have two stainless steel sinks that have an air gap between the drain and the floor (there should be room for wastewater) and a separate sink for washing your hands. If you want to avoid sanitary checks and minimize the rules you have to comply with, don't plan on serving your beer at the brewery.  5 Use FDA approved materials for beer production. The equipment used must be made of safe materials such as stainless steel. Copper is an acceptable material for use in brewing, although there may be some limitations when beer comes into contact with copper during fermentation. You should avoid material such as brass because it contains lead, but in small installations this is less of a concern. Food industry materials such as polyethylene, plastic, rubber, silicone rubber at high temperatures are quite acceptable. Do not exceed temperature limits for all materials except metal. If using PVC or vinyl tubing, make sure they are FDA approved. The use of conventional garden hoses is not acceptable. Glass bottles are also likely not to be approved by the inspectorate or customers.

5 Use FDA approved materials for beer production. The equipment used must be made of safe materials such as stainless steel. Copper is an acceptable material for use in brewing, although there may be some limitations when beer comes into contact with copper during fermentation. You should avoid material such as brass because it contains lead, but in small installations this is less of a concern. Food industry materials such as polyethylene, plastic, rubber, silicone rubber at high temperatures are quite acceptable. Do not exceed temperature limits for all materials except metal. If using PVC or vinyl tubing, make sure they are FDA approved. The use of conventional garden hoses is not acceptable. Glass bottles are also likely not to be approved by the inspectorate or customers. - Barrels made of insulating material are not suitable and must be replaced, as this material will simply melt when using gas burners. Better not to use insulation at all. It is believed that Reflectix is approved for temperatures up to 117.7 C, and Armaflex (and similar types of insulation) for temperatures up to 140 degrees. Reflectix insulation is FDA approved for food contact. This is primarily because its surface is covered with aluminum foil. Thus, other types of foil-coated insulation can also be used for brewing. Armaflex and similar insulation visas are covered with elastomeric foam and have excellent performance. Typically this material is used for pipe insulation and can be used in the food industry as long as it is approved by the FDA. Wood can also be an acceptable insulating material. Plywood and treated wood are an exception as it is a material that has been coated with something other than natural oils (mineral oil is widely used, FDA approved oil treated wood). And if the tree is on fire, it will not be more harmful and toxic than, for example, a barbecue. And, if necessary, the wood can be covered with metal to protect it from the flames (too much heat can lead to the production of charcoal).For unfired vessels, wood can also be used as cladding and other types of insulation like Armaflex. Wood is better than Reflectix insulator, while Armaflex is better than wood. Pine has better characteristics than many other types of wood, especially compared to hardwoods. Wooden strips can be attached to the outer surface of stainless steel vessels using metal strips.

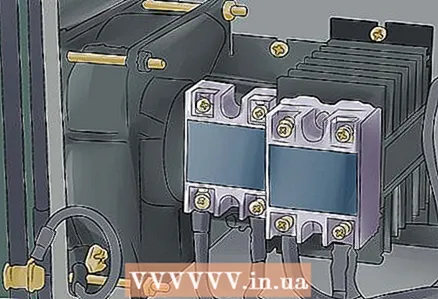

6 Use approved commercial or NEMA-rated waterproof electrical components and systems. Breweries create a humid environment that can be dangerous when combined with electricity. There are different types of NEMA enclosures. Type 4 and 4X are waterproof and are typically used in breweries. Digital temperature controllers are most often gray covered with a NEMA housing. Electronic devices can often be enclosed in a NEMA enclosure and connected to a NEMA conduit. Even if you are using NEMA enclosures, but the local inspector sees electrical components and systems that are not fully compliant, they may not approve the design. Make sure all electrical devices and systems, including sockets, fuses and wires, are correct.

6 Use approved commercial or NEMA-rated waterproof electrical components and systems. Breweries create a humid environment that can be dangerous when combined with electricity. There are different types of NEMA enclosures. Type 4 and 4X are waterproof and are typically used in breweries. Digital temperature controllers are most often gray covered with a NEMA housing. Electronic devices can often be enclosed in a NEMA enclosure and connected to a NEMA conduit. Even if you are using NEMA enclosures, but the local inspector sees electrical components and systems that are not fully compliant, they may not approve the design. Make sure all electrical devices and systems, including sockets, fuses and wires, are correct. - Many home brewing installations, especially Tier 3 gravity installations, do not use electrical components. This is perfectly acceptable. However, large or more complex installations such as the 45.46 liter RIMS and other 90.92 liter units can use electric heating elements, electronic control systems and electric pumps. If your home brewing system has non-NEMA electronics, it is best to remove them completely. Yes, your system will be at risk, but you can make it work.

- Certain pump models, such as the March Pump 409, are designed for high temperatures, and the motor is not NEMA covered, may be an exception, depending on the opinion of the local inspector. However, they must be reliably grounded and used in accordance with safety regulations. However, it is best to use pumps with motors in waterproof NEMA housings.

7 Install appropriate gas burners and use proper ventilation. Improper use of a gas burner can emit lethal concentrations of carbon monoxide and cause a fire. You probably need to use indoor burners, so replace your burners as needed and make sure they can be powered up in your room. If the brewery is located next to a large cargo hatch that can provide adequate ventilation, open burners connected to propane tanks (such as barbecues) will do just fine. Use special stoves, like in restaurants, if you cannot replace the gas burners and do not have sufficient ventilation. If the cargo door is not enough, it is important that you have a vent that is sufficient for all burners. This means that there must be a hole in the room that will cover your entire brewing system. It is also important in order to draw out the vapors obtained from the boiling wort.

7 Install appropriate gas burners and use proper ventilation. Improper use of a gas burner can emit lethal concentrations of carbon monoxide and cause a fire. You probably need to use indoor burners, so replace your burners as needed and make sure they can be powered up in your room. If the brewery is located next to a large cargo hatch that can provide adequate ventilation, open burners connected to propane tanks (such as barbecues) will do just fine. Use special stoves, like in restaurants, if you cannot replace the gas burners and do not have sufficient ventilation. If the cargo door is not enough, it is important that you have a vent that is sufficient for all burners. This means that there must be a hole in the room that will cover your entire brewing system. It is also important in order to draw out the vapors obtained from the boiling wort.  8 Prevent grain explosions. Some simple breweries simply use malt extract instead of grain, but like the vast majority of commercial breweries, you are likely to use food grains. It is a known fact that grain dust causes explosions. When brewing beer, open flames can pose a potential explosion hazard. So it's best to have a separate ventilated milling section, and a separate brewing area. This should be a place to store grain, because any grain can be easily ignited by sparks from a burner.If your mill is automatic, you will have to use an enclosed, explosion-proof motor, or you will have to grind the grain by hand. If your room is not large enough for a dedicated grain storage room, your inspector may decide to limit the amount of grain you can store on your brewery grounds.

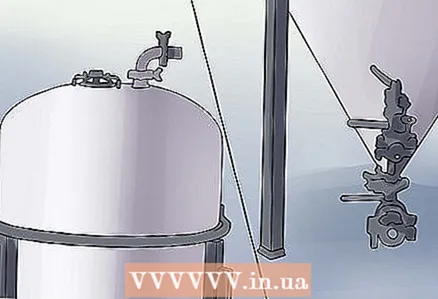

8 Prevent grain explosions. Some simple breweries simply use malt extract instead of grain, but like the vast majority of commercial breweries, you are likely to use food grains. It is a known fact that grain dust causes explosions. When brewing beer, open flames can pose a potential explosion hazard. So it's best to have a separate ventilated milling section, and a separate brewing area. This should be a place to store grain, because any grain can be easily ignited by sparks from a burner.If your mill is automatic, you will have to use an enclosed, explosion-proof motor, or you will have to grind the grain by hand. If your room is not large enough for a dedicated grain storage room, your inspector may decide to limit the amount of grain you can store on your brewery grounds.  9 Implementation of the fermentation strategy. If you want to minimize your costs, you can use special stainless steel refrigerators for the fermentation process to create your home brew. Blichmann and MoreBeer fermentors as well as other brewery products such as counterflow and cooling plates should work just fine. A cone cooler is another option besides 34-liter cones and refrigerators, but make sure it is connected in accordance with all required standards. It is perfectly acceptable to use plastic fermentors and are cheaper than stainless steel cones. The third option is a small, glycol cooled cone with a standalone portable glycol system designed for use in breweries and wineries. Portable glycol chillers can be connected directly to the tank without the need for complex glycol line systems. If you are using a 476.9 or 794.9 liter fermentation tank, make sure you can fill it. This means stacking successive brews over a long day.

9 Implementation of the fermentation strategy. If you want to minimize your costs, you can use special stainless steel refrigerators for the fermentation process to create your home brew. Blichmann and MoreBeer fermentors as well as other brewery products such as counterflow and cooling plates should work just fine. A cone cooler is another option besides 34-liter cones and refrigerators, but make sure it is connected in accordance with all required standards. It is perfectly acceptable to use plastic fermentors and are cheaper than stainless steel cones. The third option is a small, glycol cooled cone with a standalone portable glycol system designed for use in breweries and wineries. Portable glycol chillers can be connected directly to the tank without the need for complex glycol line systems. If you are using a 476.9 or 794.9 liter fermentation tank, make sure you can fill it. This means stacking successive brews over a long day. - If you want to install a large, non-portable glycol system of various components, it is best to wait until your project is approved. After that, you can buy refrigerants, compressors, glycol tanks, pumps and solenoid valves. A small, bright tank or serving vessel is a great idea and you can quickly add carbonate to your beer.

10 Pack your beer using simple, inexpensive methods. You won't be bottling a lot of beer, so pack it as you would at home. It is a good idea to use a 750 ml wine container. bottles that meet all standards. Use a plain lidded can for home brew or 22.73 liter kegs. Of course, 794.9 liters is significantly more than the brewery will produce in one or even two days. A pump that turns itself off, such as a diaphragm pump, can be used to keep the wine filler full when connected to the fermentation tank or tank. Remember that special kegs must be cleaned with an expensive cleaning machine that uses a centrifugal pump and a cleaning tank.

10 Pack your beer using simple, inexpensive methods. You won't be bottling a lot of beer, so pack it as you would at home. It is a good idea to use a 750 ml wine container. bottles that meet all standards. Use a plain lidded can for home brew or 22.73 liter kegs. Of course, 794.9 liters is significantly more than the brewery will produce in one or even two days. A pump that turns itself off, such as a diaphragm pump, can be used to keep the wine filler full when connected to the fermentation tank or tank. Remember that special kegs must be cleaned with an expensive cleaning machine that uses a centrifugal pump and a cleaning tank. - Consider how much space you need to store beer in bottles and kegs, as well as empty bottles and barrels. Bottled and keg beers (which are allowed to be stored in bottles and barrels) will need to be stored for up to three weeks.

11 Practicing proper waste disposal. Recycling waste can be costly and troublesome. Microbreweries are often not allowed to discharge most of their liquid waste into the city's sewers. This is not only because breweries use a large number of chemical detergents. Yeast, which is discharged into the sewer in large quantities, puts a lot of pressure on the sewer system. Often, the only option is to keep the waste bin open. Such a tank is filled with liquid waste and periodically emptied into a disposal truck. Additionally, you will have to install a ladder that will lead to the tank. Fortunately, it is perfectly acceptable for breweries to dump their waste down the drain while they are using approved chemicals. However, be prepared to follow these steps if your inspector requires it.

11 Practicing proper waste disposal. Recycling waste can be costly and troublesome. Microbreweries are often not allowed to discharge most of their liquid waste into the city's sewers. This is not only because breweries use a large number of chemical detergents. Yeast, which is discharged into the sewer in large quantities, puts a lot of pressure on the sewer system. Often, the only option is to keep the waste bin open. Such a tank is filled with liquid waste and periodically emptied into a disposal truck. Additionally, you will have to install a ladder that will lead to the tank. Fortunately, it is perfectly acceptable for breweries to dump their waste down the drain while they are using approved chemicals. However, be prepared to follow these steps if your inspector requires it.

Tips

Before asking for approval for your project, find a suitable building to house your brewery, fully research local brewery laws and the government approval process.Obtain all required documentation and consult with government officials.

- If there is a brewery near you, visit it and ask the owner to share their experience with you during the project approval process. Also discuss approved equipment and the overall brewing process.

- In some cases, work must be done in accordance with certifications (for example, it must be approved by a certified electrician) in order to be approved by local authorities or inspectors. Always check if a job needs to be approved by a professional first.

Warnings

- Do not modify, remove or add anything to the brewery installation unless you know how to do it in a safe manner that complies with local regulations. If necessary, use the services of certified electricians and other professionals who know the regulations.

What do you need

- Convenient location

- Fitted floor, drains

- Food processing equipment

- Brewing equipment

- Gas-burners

- Slabs

- Ventilation

- Stainless steel cones

- Glycol system

- Keg / bottle filling system